Inventory Control

Complete inventory management

system allows several costing methods, multiple

warehouse locations, lot tracking, and more.

Reports allow you to analyze and control your

stock. Complete link to Purchasing, Sales Orders,

Accounts Receivables, and General Ledger.

Integrates with kits and bill of materials.

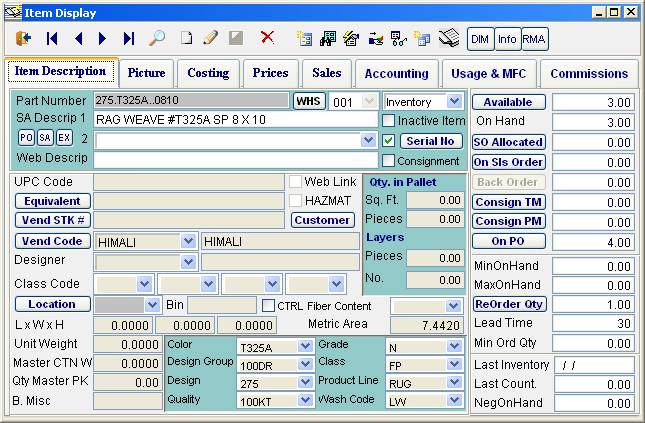

Inventory Master -

Item Description

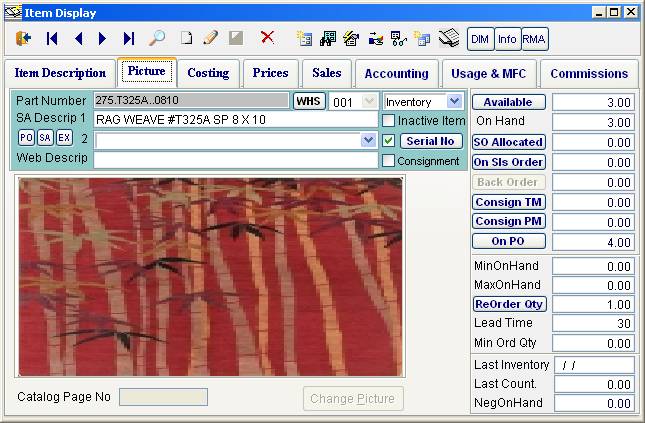

Inventory Master - Item Picture

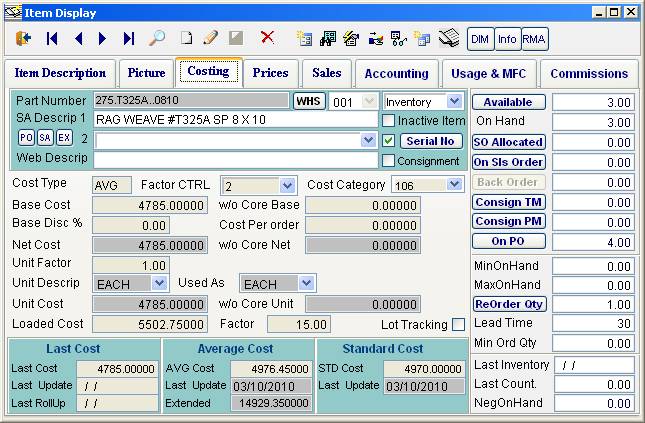

Inventory Master -

Item Costing

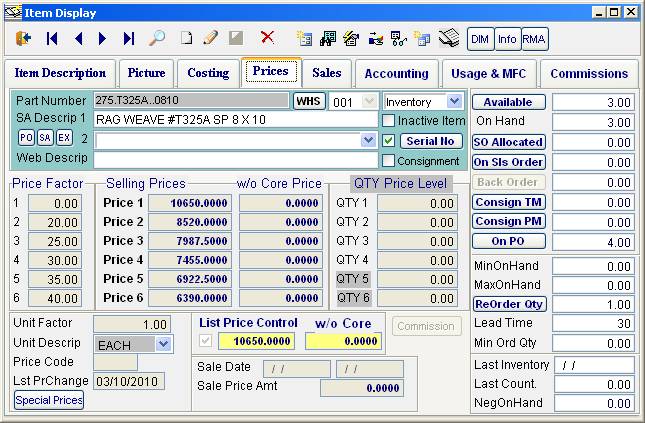

Inventory Master -

Item Prices

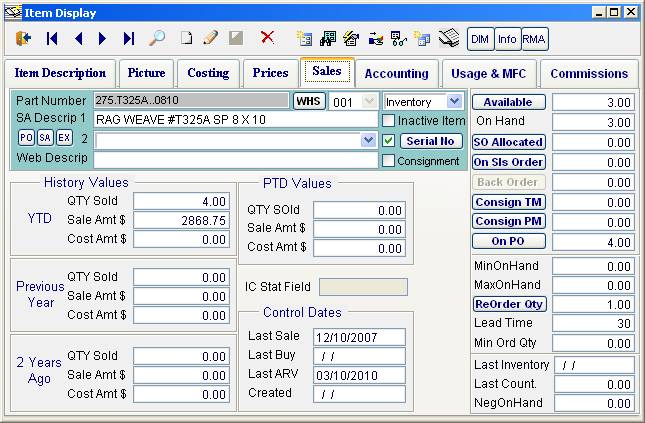

Inventory Master -

Item Sales

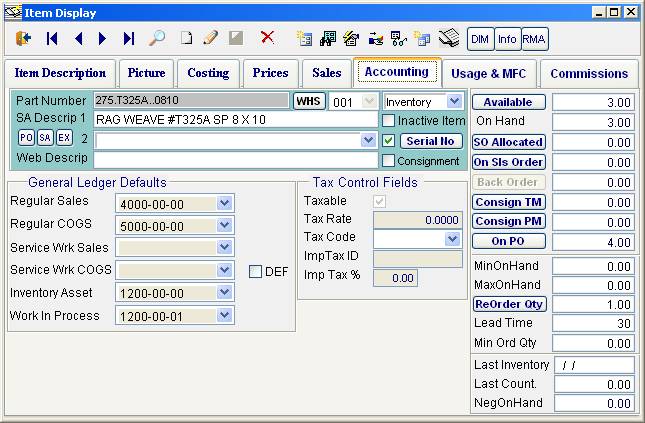

Inventory Master -

Item Accounting

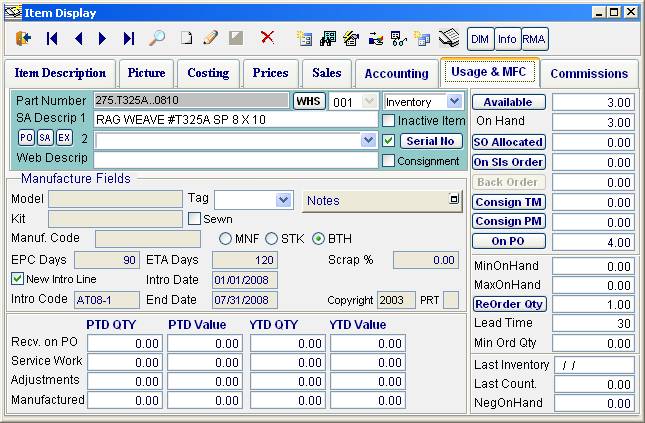

Inventory Master -

Item Usage and Manufacturing

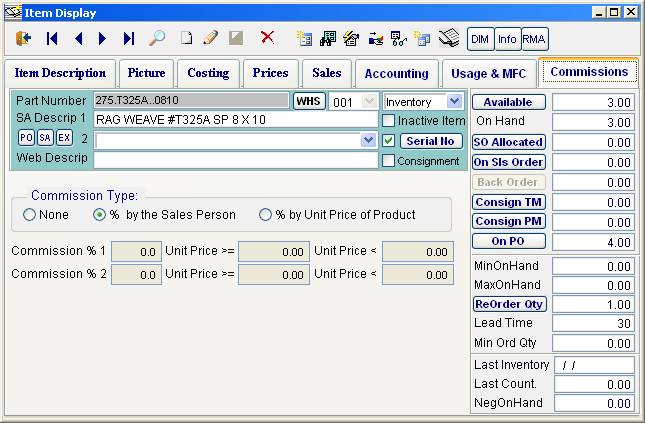

Inventory Master -

Item Commission

Inventory Master -

Serial Number Status

- Select one of four different cost

methods, Average, FIFO, LIFO, or Last Cost.

- Multiple warehouse locations

per item.

- Multiple locations within

each warehouse.

- Define units of measure for

purchasing and selling.

- Define each item with a Part

number, UPC code, unlimited vendor part

numbers, unlimited customer part

numbers, unlimited equivalent part numbers.

- Separate item description for

purchasing and sales.

- Each item has an extended

description with unlimited number of

characters.

- Unlimited bin locations per

item.

- Item types include:

Inventory, Non IC, Raw Material, Kit, Service,

and Component.

- Define unit of weight.

- Carton pack and qty per

carton.

- Item origin either from

stock, manufacture or both.

- Include picture of inventory

item on display screen.

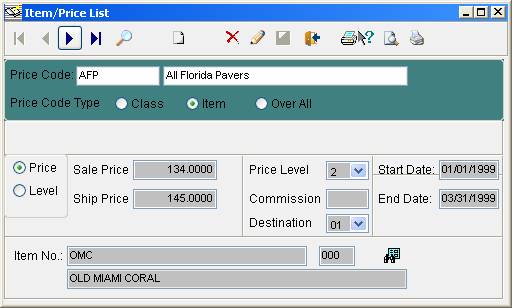

- Each item can have multiple

price schedules. Can be defined by

customer, by markup from cost, by discount

from list price, by volume, by product code.

- Six price factors per

item. Calculate markup from cost or

markdown from list price.

- Six (6) quantity price level

for each item. Selling price determined

by quantity of item purchased.

- Customer specific price

control for each item.

- Each item can be assigned a

promotion price with expiration date.

- Allows for multiple vendors

for same part number.

- Classify each item by one

class code and up to three sub class codes.

- Master parts display shows

item status: Available, On Hand,

Committed-to-Ship, Committed, Back Ordered, On

Order, Min-On hand, Max-On-Hand, Re-Order

quantity, Minimum Order Quantity, Last Stock

count date, last physical count, negative

variance.

- Assign catalog page number

item appears in.

- User defined status field.

- Flexible unit cost

definition: Base cost, Discount percentage

from base cost, net cost, Unit factor, Unit

cost, landed cost, average cost.

- Allow each item to define tax

status, tax rate, tax code, import tax

percentage.

- Define GL link for each item:

Sales, Asset, Cost and Service GL account.

- Item master display screen

shows sales history: period-to-date,

year-to-date, previous year, two (2) years

ago. Both quantities sold and dollar

value. Displays last sale date, last buy date,

last arrival date, date item created.

- Query system by class code

and item type for fast on-line searches.

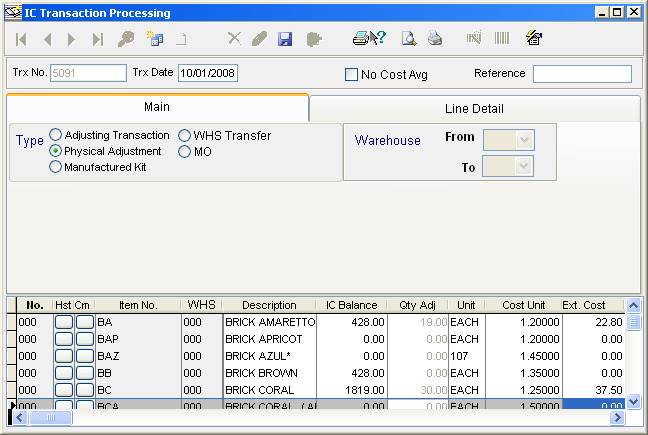

- Transaction processing system

that allows adjusting stock quantities,

warehouse transfer, or physical count

adjustments.

- Transaction processing links

to GL to adjust costs (inventory valuation).

- Basic bill of materials for

kits.

- Automatically deducts raw

material stock from kit items at time of kit creation.

- Complete lot tracking control

through item life cycle: purchase order,

sales order, to invoice.

- History look-up of lots by

entry number, invoice number, sales order

number.

- Allows for warehouse maintenance

function. Create up to 65,000 different

warehouse locations.

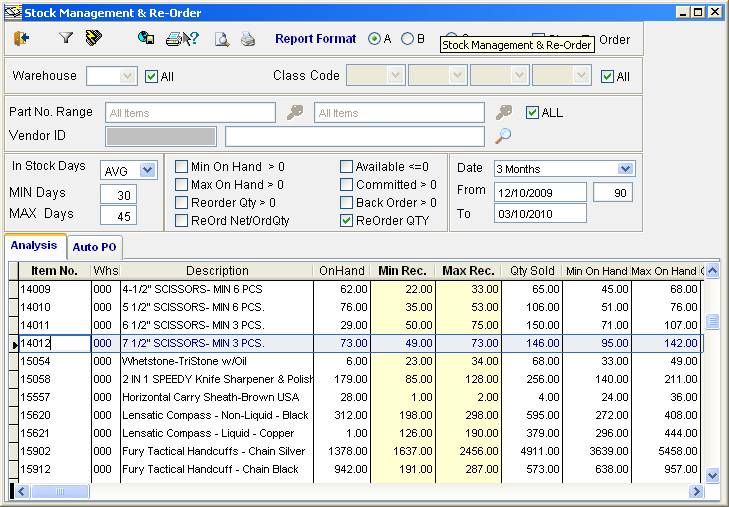

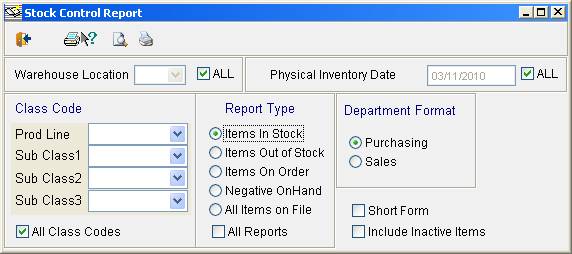

Reports

- General item listing report.

- Price labels.

- Items in stock report.

- Items out of stock report.

- Items on order report.

- Stock count work sheets report.

- Warehouse bin location report.

- Stock re-order report.

- Inventory adjustments report.

- Kit creation report.

- Inventory physical count report.

- Parts status report.

- Lot tracking control report.

- General Ledger Distribution report.

Lot

Tracking

The lot tracking system allows you

to assign a control number to your incoming

stock. This number follows the item through

the sales cycle and can be recalled from history.

- Assign lot numbers manually

or auto generate them.

- Lots can be assigned at time

of PO receipt or after the fact.

- Mark an item as bonded

inventory.

- Only "cleared"

items can be transferred into sellable stock.

- Track lots through sales

cycle into sales history.

- Reports

- Lots by item.

- Cleared items.

- Adjustment register by lots.

- Sales history by lot number.

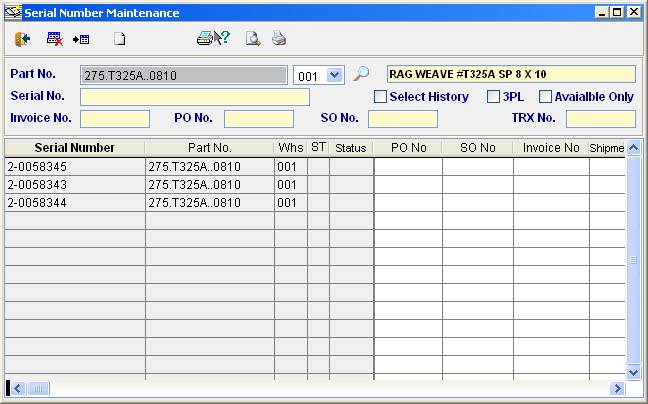

Serial

Numbers

The Serial Number capabilities of

VFP allows tracking serial number from the PO

receipt to the final sales invoice.

- Alpha numerical serial number

field.

- Identify inventory items as

serialized or not.

- Assign serial numbers to

incoming stock during purchase order

receiving.

- Pick serial numbers during

order entry or invoicing.

- Serial number history lookup.

- Scan serial numbers during

sales and purchase processing.

- Reports

- List serial number for one

part number

- Select all serial number for

an invoice, sales order, purchase order or

inventory transaction..

Kits

The KIT functions allows for a

simple bill of material system. Create a

bill of material list for unlimited number of

items.

- Enter kit on fly.

- Assign unlimited number of

items to a kit.

- Allow sub kits to be

assigned.

- Automatic cost calculation

based on component count.

- Create an inventory

transaction to enter a kit into stock.

- Automatically adjust stock on

kit creation.

- Automatically adjust cost and

price for kits.

- Reports

- Bill of materials list by

item number.

- IC transaction register for

manufactured kits.

|